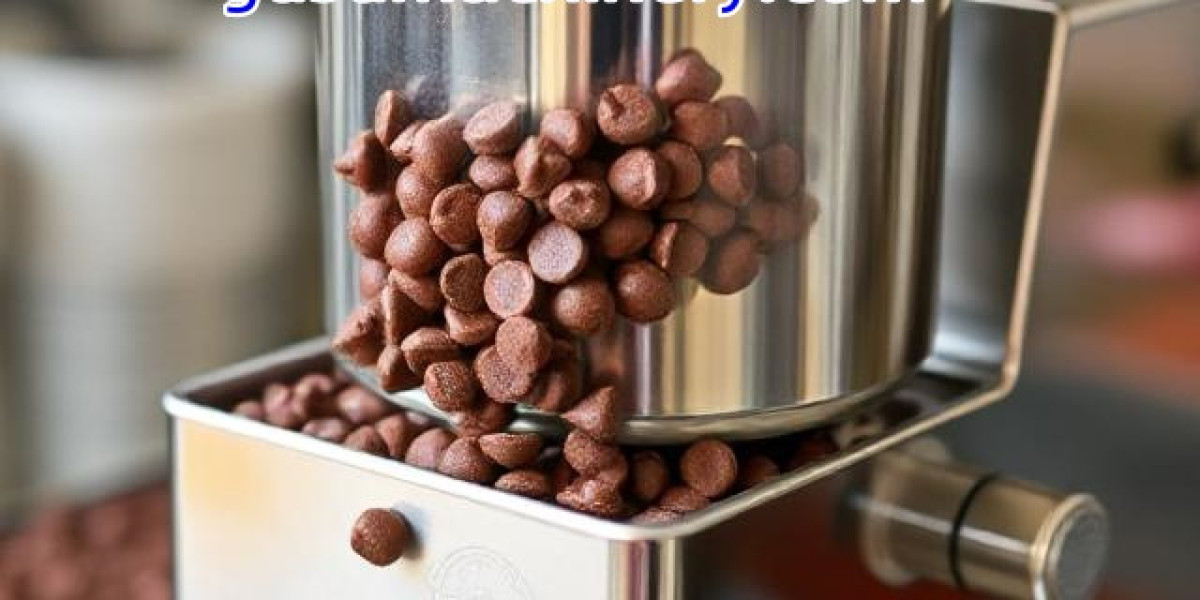

Gusu Chocolate Depositor settings play a crucial role in achieving consistent chocolate shapes, textures, and overall product quality in confectionery production. Proper adjustment ensures that each piece meets desired specifications while minimizing material waste and production delays.

Operators should begin by monitoring chocolate viscosity and temperature. Maintaining a stable temperature prevents excessive dripping or uneven flow, which can compromise the final product's appearance. Adjusting the flow rate and timing of the depositor ensures that the chocolate is distributed evenly across molds, reducing inconsistencies during packaging.

Nozzle configuration is another important factor. Different shapes and sizes of chocolate molds require slight adjustments to nozzle height and angle. Aligning the nozzle properly ensures that chocolate fills molds precisely without overflow, helping maintain uniformity across batches. Operators can also rotate mold positions or adjust conveyor speed to optimize alignment with the depositor output.

Regular maintenance contributes to smooth operation. Cleaning the machine, inspecting seals, and checking pumps prevent interruptions in chocolate flow. Gusu provides practical guidance and spare parts, allowing operators to handle minor issues efficiently and reduce downtime. Scheduled maintenance also prolongs the service life of key components and maintains consistent output quality.

Monitoring production feedback is essential. Evaluating each batch for weight, shape, and surface quality allows operators to fine-tune settings gradually. Adjusting parameters in response to environmental factors, such as humidity or chocolate type, ensures consistent results. Training operators to recognize subtle variations in flow and texture improves overall efficiency and reduces material loss.

By combining careful setup, routine maintenance, and attention to process variables, confectionery teams can maximize the efficiency of chocolate depositor machines. Gusu equipment is designed to support these practices, enabling predictable and stable production. More details on their applications are available at https://www.gusumachinery.com/