Glass Fiber-Reinforced Plastics (GFRP) Market Overview

The Glass Fiber-Reinforced Plastics (GFRP) Market Trend is a rapidly growing segment in the composites industry, driven by increasing demand for lightweight, durable, and corrosion-resistant materials across various industries. GFRP composites are made by reinforcing plastic matrices with glass fibers, offering a unique combination of high tensile strength, flexibility, and cost-effectiveness. These materials are extensively used in automotive, aerospace, construction, marine, wind energy, and electrical applications.

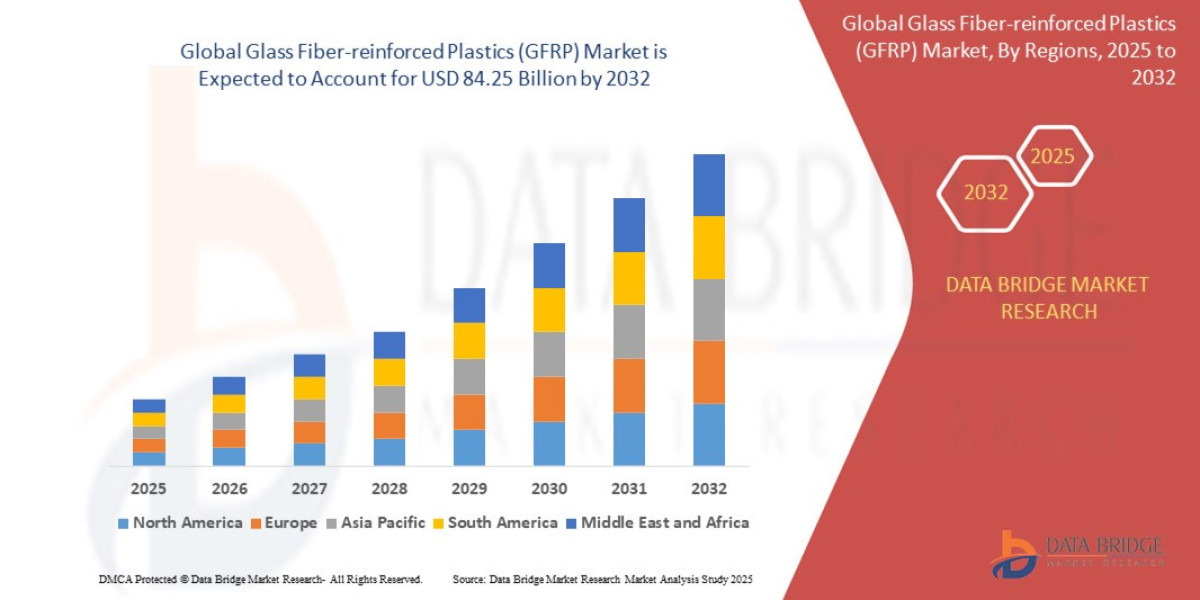

The global Glass Fiber-Reinforced Plastics (GFRP) Market was valued at USD 50.72 billion in 2024 and is projected to reach USD 84.25 billion by 2032, growing at a CAGR of 6.55% during the forecast period. This growth is fueled by the shift toward lightweight materials for fuel efficiency, infrastructure modernization, and rising adoption of composite materials in sustainable manufacturing.

Competitive Landscape

The Glass Fiber-Reinforced Plastics (GFRP) Market is moderately consolidated, with leading players focusing on innovation, expansion, and partnerships to strengthen their market presence. Prominent market participants comprise Owens Corning (U.S.), JEC (France), PPG Industries, Inc. (U.S.), Johns Manville (U.S.), Saint-Gobain (France), Nippon Sheet Glass Co., Ltd (Japan), AGY Holding Corp. (U.S.), Chongqing Polycomp International Corp. (China), Taishan Fiberglass Inc. (China), Taiwan Glass Ind. Corp. (Taiwan), BASF (Germany)

Request Sample For Glass Fiber-reinforced Plastics (GFRP) Market @ https://www.databridgemarketresearch.com/request-a-sample?dbmr=global-glass-fiber-reinforced-plastics-gfrp-market

GFRP Market Driver

- Rising Demand for Lightweight and High-Performance Materials

The increasing emphasis on fuel efficiency and emission reduction in the automotive and aerospace sectors has significantly boosted the demand for lightweight materials. GFRP composites are replacing traditional materials such as steel and aluminum due to their superior strength-to-weight ratio and corrosion resistance. In transportation, they contribute to weight reduction, improved performance, and enhanced design flexibility.

- Technological Advancements in Manufacturing and Processing

Continuous innovation in resin systems, fiber architecture, and processing technologies has enhanced the mechanical properties and production efficiency of GFRP composites. Techniques such as pultrusion, filament winding, and resin transfer molding (RTM) are being widely adopted for large-scale manufacturing. Additionally, automation and digital monitoring systems are improving product consistency and reducing waste.

- Sustainability and Recycling Initiatives

Environmental concerns are driving the adoption of eco-friendly GFRP manufacturing processes and recycling technologies. Researchers and manufacturers are focusing on developing bio-based resins and recyclable thermoplastic matrices to minimize the environmental footprint. The trend toward circular economy practices in composite material production presents new opportunities for sustainable innovation.

GFRP Market Segmentation

By Resin Type:

- Polyester Resin

- Epoxy Resin

- Vinyl Ester Resin

- Polyurethane Resin

- Others

By Manufacturing Process:

- Hand Lay-Up

- Spray-Up

- Filament Winding

- Pultrusion

- Resin Transfer Molding (RTM)

- Compression Molding

- Others

By Application:

- Automotive & Transportation

- Building & Construction

- Electrical & Electronics

- Aerospace & Defense

- Marine

- Wind Energy

- Consumer Goods

- Others

By End-Use Industry:

- Industrial

- Commercial

- Residential

Regional Insights

Asia-Pacific leads the GFRP Market, supported by strong industrial growth, urbanization, and increasing demand for lightweight materials in China, India, and Japan. The region’s expanding construction and automotive sectors are key growth drivers.

North America holds a significant share, driven by technological advancements, the presence of major composite manufacturers, and high adoption in aerospace, wind energy, and automotive applications. The focus on sustainability and renewable energy is further enhancing market prospects in this region.

Europe remains a prominent market with strong regulatory support for lightweight materials and innovation in composite recycling. Countries such as Germany, France, and the UK are at the forefront of GFRP technology development.

Latin America and the Middle East & Africa are witnessing steady growth due to increasing industrialization and infrastructure development, particularly in energy, marine, and construction sectors.

Key Market Trends

- Shift Toward Electric Vehicles (EVs): GFRP materials are increasingly used in EV components to enhance range and reduce overall vehicle weight.

- Rise in Wind Energy Applications: The demand for GFRP composites in wind turbine blades is growing as renewable energy adoption accelerates.

- Smart Composite Integration: Embedded sensors in GFRP structures enable real-time monitoring and predictive maintenance in industrial applications.

- Growth of Bio-Based Composites: Manufacturers are exploring bio-resins and recyclable fibers for eco-friendly GFRP production.

- Customization and Design Flexibility: Enhanced molding technologies enable complex designs, improving product aesthetics and performance.

Emerging Opportunities for GFRP Market

Expansion in Renewable Energy Sector

The growing global focus on renewable energy is driving the use of GFRP in wind turbine blades, which require lightweight and high-strength materials to improve efficiency and lifespan.

Infrastructure Modernization

GFRP rebar and panels are increasingly being adopted for bridges, tunnels, and buildings due to their superior corrosion resistance and long service life, offering lucrative opportunities in infrastructure projects.

Advancements in Thermoplastic Composites

Thermoplastic-based GFRP composites are gaining traction for their recyclability and improved mechanical performance, creating new growth avenues for sustainable material solutions.

Growing Demand from Aerospace and Defense

The aerospace sector’s need for high-strength, low-weight materials to improve fuel efficiency and performance is fueling the use of advanced GFRP composites.

GFRP Market Future Outlook

The Glass Fiber-Reinforced Plastics Market Outlook is poised for robust growth, supported by advancements in material technology, sustainability initiatives, and expanding end-use industries. As industries continue to prioritize lightweight, durable, and recyclable materials, GFRP composites will remain integral to future innovations in construction, mobility, and renewable energy.

Future trends indicate increasing automation in composite manufacturing, greater use of thermoplastic matrices, and integration of smart technologies for performance optimization. Companies that invest in sustainable production, material innovation, and global expansion are expected to lead the GFRP Market through 2032 and beyond.

About Us:

Data Bridge is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact :

Data Bridge Market Research Private Ltd .

3665 Kingsway — Suite 300 Vancouver BC V5R 5W2 Canada

+1 614 591 3140 (US)

+44 845 154 9652 (UK)