Evolving Role of Analytical Outsourcing

Over the past decade, medical device manufacturing has undergone a dramatic transformation. The rapid adoption of nanotechnology, bio-resorbable polymers, and hybrid materials has increased the complexity of validation processes. Internal quality assurance teams often lack the advanced instrumentation and certified cleanroom environments required for comprehensive testing. Outsourcing analytical testing to specialized third-party laboratories bridges this critical gap.

Analytical service providers offer a breadth of expertise — from chemical characterization and microbiological validation to extractables and leachables (E&L) testing. These procedures confirm that the raw materials, coatings, and packaging used in devices remain stable, biocompatible, and safe for human contact. Without such validation, manufacturers face significant delays in regulatory submissions and product approvals.

Outsourcing also allows companies to optimize operational costs. Establishing and maintaining in-house analytical labs can demand millions in capital expenditure, especially with fast-evolving compliance standards from agencies like the U.S. FDA, EMA, and PMDA in Japan. By partnering with accredited laboratories, medical device firms can focus resources on innovation and production while maintaining compliance through certified service providers.

Regulatory Pressure and Quality Imperatives

The increasing stringency of medical device regulations has accelerated the demand for specialized testing partners. The European Union’s Medical Device Regulation (MDR 2017/745) and the U.S. FDA’s evolving Quality System Regulation both require extensive material and biological compatibility assessments.

Analytical outsourcing firms provide not only technical testing but also regulatory consulting, helping manufacturers navigate global submission pathways. Laboratories maintain certifications such as ISO 17025, GLP, and cGMP, ensuring data integrity and audit readiness. This combination of testing and compliance support makes outsourcing an attractive, risk-reducing strategy for both emerging and established device makers.

Moreover, the COVID-19 pandemic intensified scrutiny of sterilization processes, contamination control, and supply-chain validation. Analytical outsourcing partners equipped with remote monitoring systems and digital data platforms allowed device developers to maintain testing continuity during lockdowns. This resilience proved the long-term value of diversified, external analytical networks.

Technological Innovations in Testing

Modern analytical testing has evolved far beyond manual microscopy and basic chemical analysis. Advanced mass spectrometry, Raman spectroscopy, high-performance liquid chromatography (HPLC), and accelerated aging simulations now allow precise quantification of impurities and degradation products.

Artificial intelligence (AI) and machine learning are increasingly being integrated into data interpretation workflows, enabling predictive modeling of material performance and device lifespan. Digital twins — virtual replicas of medical devices — can simulate stress, wear, and environmental exposure before physical testing, reducing overall validation time.

The introduction of automated sample preparation robots and cloud-connected lab information systems ensures traceability and consistency, addressing the industry’s growing emphasis on data reliability. As these technologies mature, outsourcing partners continue to invest in upgraded infrastructure, ensuring they remain indispensable to global manufacturers seeking competitive advantages through efficiency and precision.

Market Dynamics and Economic Rationale

From an economic standpoint, outsourcing analytical testing is more than a cost-saving measure — it’s a strategic decision. Global healthcare expenditure is rising, yet reimbursement pressure is forcing device makers to deliver innovation faster and cheaper. Outsourced partners provide scalability: small start-ups benefit from pay-per-test models, while large corporations gain access to specialized assays across geographies.

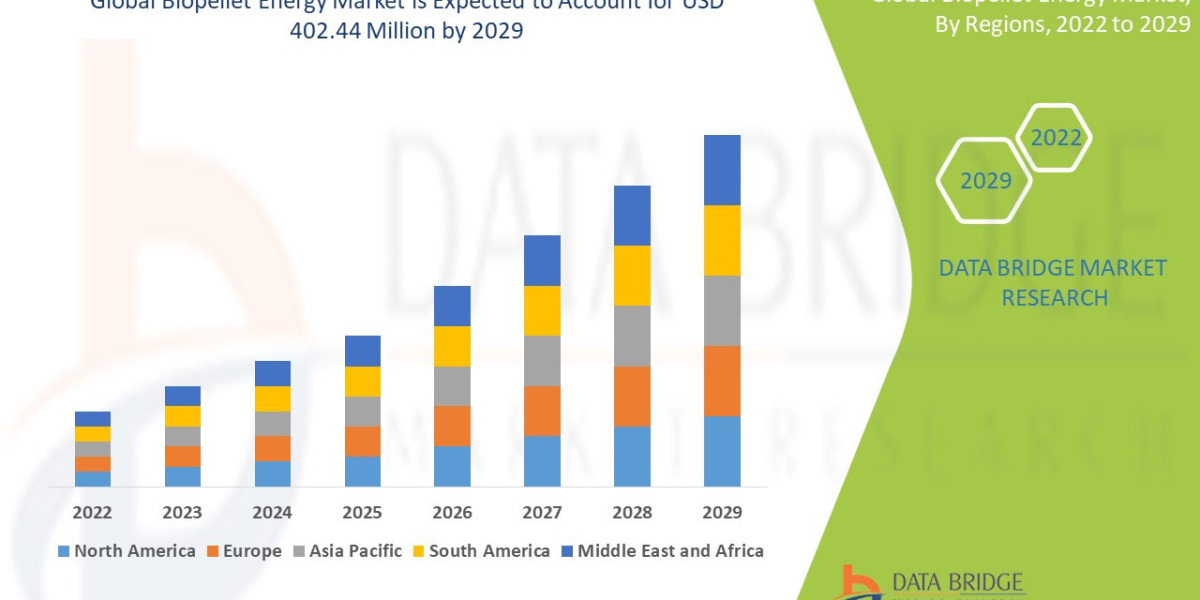

Emerging regions, particularly Asia-Pacific and Latin America, have seen a surge in contract analytical laboratories due to skilled workforce availability and lower operational costs. This globalization of testing networks not only reduces turnaround times but also diversifies supply chain risk.

Strategic collaborations between device manufacturers and CROs (Contract Research Organizations) have become the norm. Many top-tier service providers now offer integrated packages — combining analytical validation, biocompatibility testing, microbiology, and toxicology studies under one umbrella. This one-stop-shop model reduces project complexity, improves coordination, and ensures cohesive documentation for regulatory submissions.

Challenges and Future Outlook

Despite its rapid growth, the analytical testing outsourcing industry faces challenges such as data security, intellectual property protection, and harmonization of cross-regional standards. With sensitive device blueprints and proprietary formulations involved, robust cybersecurity and confidentiality agreements are critical.

However, future prospects remain overwhelmingly positive. As smart implants, nanodevices, and digital therapeutics emerge, analytical testing requirements will expand beyond chemistry and biology to include software validation, electromagnetic compatibility, and human–machine interaction assessments.

Continuous investment in digital infrastructure, blockchain-based data integrity, and AI-powered analytics will redefine how outsourcing firms deliver value. Laboratories of the future will act not merely as quality checkpoints but as innovation accelerators, supporting early-stage R&D through real-time feedback and predictive modeling.

To explore these dynamics further, visit Medical Device Analytical Testing Outsourcing Market analysis.

FAQs

What is driving the demand for medical device analytical testing outsourcing?

• Stringent global regulations, complex materials, and the need for cost-efficient compliance.Which tests are most frequently outsourced?

• Biocompatibility, extractables/leachables, sterilization validation, and material characterization.How is technology transforming analytical outsourcing?

• Through automation, AI-driven data analytics, and digital quality management systems.What are the main benefits for manufacturers?

• Reduced operational cost, faster time-to-market, and guaranteed regulatory alignment.Which regions are emerging as outsourcing hubs?

• Asia-Pacific and Eastern Europe due to affordability and expanding technical expertise.Medical Device Analytical Testing Outsourcing Market Forecast: Predicting Trends Through 2035