As per Market Research Futute, the Coiled Tubing Services market is witnessing significant growth due to the increasing demand for advanced well intervention techniques and enhanced oil recovery methods. Coiled tubing services have become an essential part of the oil and gas industry, offering efficient solutions for drilling, maintenance, and intervention in both onshore and offshore wells. With technological advancements and the rising focus on reducing operational downtime, coiled tubing services are poised to play a critical role in the global energy sector.

Overview of Coiled Tubing Services

Coiled tubing involves the use of a continuous, flexible steel pipe that is wound onto a spool and can be inserted into a wellbore without the need to remove the production tubing. This innovative technique allows for various well intervention operations such as cleaning, stimulation, and logging while minimizing production interruptions. Unlike conventional methods, coiled tubing operations can be performed under live well conditions, which makes them highly efficient and cost-effective.

The global coiled tubing services market is expanding due to several factors, including the growing need for well maintenance, enhanced recovery of mature oilfields, and the integration of smart technologies in well intervention operations. Additionally, stringent environmental regulations are driving oil and gas companies to adopt safer and less invasive intervention techniques, further boosting market adoption.

Key Applications of Coiled Tubing Services

Well Cleaning and Stimulation: Coiled tubing is extensively used for cleaning out debris, scale, and sand from the wellbore, ensuring smoother production. It also aids in hydraulic fracturing and acidizing treatments to enhance hydrocarbon recovery.

Logging and Monitoring: Coiled tubing services facilitate the deployment of sensors and logging tools to assess well conditions, monitor production, and detect potential issues early. Real-time data acquisition helps optimize production strategies and reduce operational risks.

Drilling and Completion Operations: Coiled tubing can be employed for drilling slim wells, sidetracks, and re-entry operations, offering flexibility and precision in well completion tasks. This reduces the time and costs associated with traditional drilling methods.

Plug and Abandonment: As mature oilfields reach the end of their productive life, coiled tubing plays a role in safe plug and abandonment operations, minimizing environmental impact and ensuring regulatory compliance.

Market Dynamics

Drivers

Rising Oilfield Development Activities: As exploration and production activities increase worldwide, the demand for efficient well intervention services like coiled tubing continues to grow.

Cost Efficiency and Reduced Downtime: The ability to perform operations without halting production makes coiled tubing a cost-effective solution, attracting oil and gas operators.

Technological Advancements: Innovations such as intelligent coiled tubing systems, real-time monitoring, and enhanced material strength are improving service reliability and expanding market opportunities.

Challenges

High Initial Investment: The cost of advanced coiled tubing equipment can be prohibitive for smaller operators, limiting market penetration.

Operational Risks: Despite its advantages, coiled tubing operations require skilled personnel and careful planning to avoid complications like tubing fatigue or stuck pipe incidents.

Opportunities

Expansion in Offshore Operations: Increasing offshore exploration projects, particularly in deepwater regions, are creating new growth avenues for coiled tubing services.

Integration with Digital Solutions: Adoption of digital tools and AI-driven analytics in coiled tubing operations can enhance efficiency and predict potential well issues before they escalate.

Regional Insights

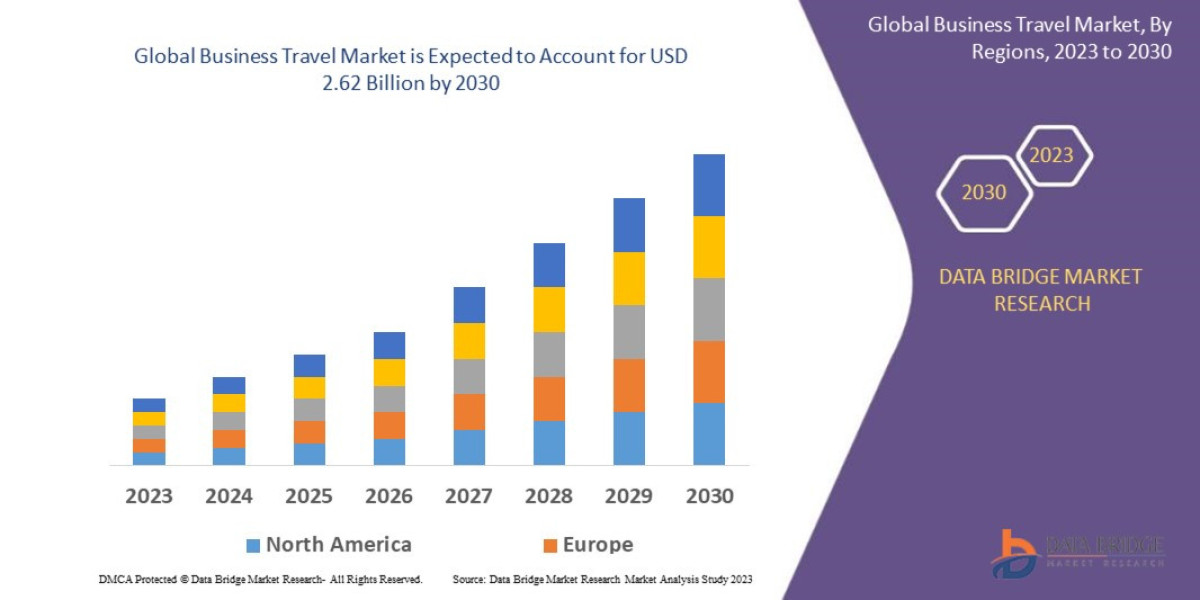

North America currently dominates the coiled tubing services market, driven by the presence of mature oilfields in the United States and Canada and a high adoption of technologically advanced intervention methods. The Asia-Pacific region is emerging as a key market due to increased offshore exploration activities and rising energy demand in countries like China and India. Europe and the Middle East are also witnessing steady growth, supported by investments in oilfield maintenance and recovery projects.

Future Outlook

The coiled tubing services market is expected to continue its upward trajectory, fueled by technological innovations, the growing need for cost-efficient well interventions, and the emphasis on environmentally sustainable practices. Companies investing in smart coiled tubing solutions and digital integration are likely to gain a competitive edge in the evolving energy landscape.

FAQs

Q1: What are coiled tubing services used for?

Coiled tubing services are used for well cleaning, stimulation, logging, monitoring, drilling, completion, and plug-and-abandonment operations in oil and gas wells.

Q2: How does coiled tubing improve operational efficiency?

Coiled tubing allows for intervention operations without halting production, reducing downtime and operational costs while enabling precise and flexible well interventions.

Q3: Which regions have the highest adoption of coiled tubing services?

North America leads the market due to mature oilfields and technological adoption, while Asia-Pacific, Europe, and the Middle East are growing markets due to increasing exploration and offshore activities.

More Related Reports: